How to Choose Cotton Linter Paper Manufacturers in India?

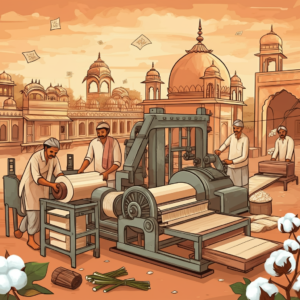

The production of cotton linter paper in India has become increasingly popular due to the rising demand for environmentally friendly and sustainable paper goods. The short fibres that remain on cottonseed after ginning are called cotton linters, and they are rich in cellulose and perfect for making high-quality paper. Being one of the biggest cotton producers, India provides a wealth of raw materials for this specialised yet essential part of the paper industry.

Cotton linter paper production offers an alternative to wood-based paper by fusing traditional farming methods with contemporary sustainability objectives. This article examines every aspect of the production of cotton linter paper in India, including sourcing, processing, important players, uses, and industrial obstacles.

Cotton Linter Paper: What Is It?

The soft, fuzzy fibres that stick to cotton seeds are called cotton linters, and they are used to make cotton linter paper. High-quality, long-lasting, archival-grade paper is made from the cellulose that is extracted from these fibres. Cotton linter paper is superior to wood-pulp paper for money paper, security documents, high-end stationery, and artistic applications because it is acid-free, lasts longer, and has a smoother texture.

Why India Is a Major Player in the Production of Cotton Linter Paper?

India is a perfect location for enterprises based on cotton linter because it is one of the biggest producers of cotton in the world. India’s production of cotton linter paper is both feasible and competitive worldwide due to several factors:

• Abundant Raw Material: India produces a significant amount of cotton linters every year due to the country’s millions of hectares of cotton production.

• Labour Cost Advantage: Manual inspection and quality control are made possible by inexpensive labour, which also reduces manufacturing costs.

• Government Support: Several national and state laws encourage agro-based and sustainable industrial sectors.

• Export Potential: Cotton linter paper is exported by Indian producers to several nations, particularly those with a need for security or archival paper.

India’s Process for Manufacturing Cotton Linter Paper

1. Gathering and classifying cotton liners

First-cut and second-cut linters are sourced from cottonseed oil mills to start the process. For high-quality paper, first-cut linters are recommended because of their longer fibres. To get rid of dirt, seeds, and contaminants, the linters are cleaned thoroughly.

2. The Process of Pulping

To convert the cleansed linters into cellulose pulp, they undergo chemical pulping, most frequently with sodium hydroxide (alkaline pulping). The pulp is whitened using bleaching agents such as hydrogen peroxide or chlorine-free substitutes.

3. Making the Pulp Better

Depending on the paper’s intended purpose, the pulped cotton linters are refined in beaters or refiners to modify the fibre properties, including length, hydration, and bonding potential.

4. Formation of Sheets

The refined pulp is spread onto a moving mesh after being diluted with water using a cylinder paper machine or a Fourdrinier. A thin coating of fibre remains after the water is removed by gravity and suction, and it is subsequently compressed and dried to create sheets.

5. Calendaring and Drying

For drying, the damp sheets go through a succession of cylinders heated by steam. The dried paper is passed between rollers in the calendaring stage to improve uniformity in thickness, gloss, and smoothness.

6. Cutting and Completing

The completed paper is packaged for delivery after being cut into the appropriate sizes, such as rolls or reams. Additional finishing, such as coating, dyeing, or watermarking, may occasionally be carried out for aesthetic or security purposes.

Cotton Linter Paper Applications

Cotton linter paper is utilised in many different industries because of its excellent quality and longevity:

• Currency and Banknote Paper: Because of its durability and strength, government-approved mills use it to produce currency.

• Security Paper: Because it has anti-counterfeiting and watermarking capabilities, it is perfect for legal papers, passports, and certifications.

• Fine Art and Stationery: Because of its texture and archival qualities, cotton linter paper is preferred by artists and high-end stationery businesses.

• Bible and Religious Text Paper: Ideal for printing holy texts, this paper is sturdy and lightweight.

Because of their great absorbency and purity, filter paper and technical papers are used in labs, tea bags, and industrial filters.

What are the Benefits of Producing Paper with a Cotton Linter?

1. Eco-friendliness and sustainability

Since they are a by-product of the cotton industry, using cotton linters to make paper is a zero-waste solution. Deforestation is not necessary for them.

2. Outstanding Quality

Cotton linter paper is ideal for archival and high-end applications since it is inherently acid-free, strong, and resistant to yellowing over time.

3. Recyclable and biodegradable

Cotton paper can be recycled safely and is 100% biodegradable, which lessens the impact on the environment.

4. A High Content of Cellulose

In the production of paper, the 85–95% cellulose content of cotton linters guarantees strength, absorbency, and superior forming.

Obstacles in India’s Cotton Linter Paper Production

India’s cotton linter paper manufacturing sector has a bright future, but several obstacles prevent it from reaching its full potential. Given that their supply is mostly dependent on regional agricultural practices and seasonal cotton growing, one of the main problems is the irregular availability of cotton linters.

The availability and pricing of raw materials fluctuate as a result. Furthermore, turning cotton linters into usable paper pulp requires bleaching and pulping procedures that use a lot of energy and chemicals, making the process costly and technically complex. The consistency and calibre of the finished product are further impacted by the fact that many small and medium-sized businesses struggle with antiquated equipment, a lack of automation, and restricted access to contemporary processing technology.

Due to economic concerns and ignorance of the environmental advantages, many customers continue to favour traditional wood-based paper, and market awareness of cotton linter paper is relatively low. The industry’s operational complexity is further increased by regulatory barriers, a lack of R&D funding, and competition from synthetic or less expensive paper substitutes. For India’s cotton linter paper industry to flourish sustainably, these issues must be addressed through legislative backing, technology advancements, and awareness-raising initiatives.

Conclusion

India is in a unique position to take the lead in the production of cotton linter paper because of its extensive cotton-growing regions and papermaking heritage. Cotton linter paper provides a sustainable, environmentally friendly substitute for paper goods made from wood, as sustainability emerges as a major subject throughout industries.

This paper, made of natural fibres, is finding its way into many other fields, including religious texts, government security documents, and artistic uses. India can become a global centre for cotton linter paper exports and innovation in the years to come by resolving current issues and utilising its advantages in raw materials.